PermAmelt

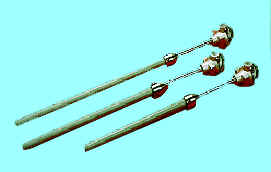

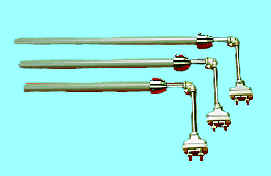

Thermocouple

Protection Tube

New Engineering ceramic for

use in molten Aluminum

|

FEATURES

-

Quick response

-

Maintenance free

-

Prolonged Service life

-

High oxidation resistance

-

No contamination of the bath

-

Excellent thermal shock resistance

-

Low thermal expansion coefficient

-

No corrosion from molten alumina

-

High strength up to

1,000°C covering the range of molten aluminum.

|

|

DESCRIPTION

Closely resembling to metal, PermAmelt

is a new unique engineering ceramic. it is good choice as thermocouple

protection tubes and immersed heater protection tubes for use in molten aluminum

baths, even where there are rapid temperature fluctuations. Due

to impermeable and non-wetting surface of PermAmelt,

the thermocouples assemblies need no daily washing or coating thereby proving

use maintenance free use in molten aluminum baths, much longer than any other

protection tube material.

PermAmelt thermocouple protection tubes require no preheating due to

their low thermal expansion coefficient and thermal shock resistance. Their low

heat conductivity helps to prevent temperature drop in the molten aluminum bath

and contributes to energy conservation. Since

the tubes are of ceramic material, there is no iron pick-up to create inclusion

in the aluminum.

TECHNICAL PROPERTIES OF

PERMAMELT

|

BULK

DENSITY (g/cm³)/ ( RELATIVE DENSITY

%)

|

3.10~3.15/

(97~98) |

|

BENDING STRENGTH (Kg/mm²) At Room Temp.

At 1,000°C

At

1,200°C

At 1,400°C |

60~70

40~45

30~35

— |

|

COMPRESSIVE STRENGTH (Kg/mm²)

At Room Temp.

|

170~190

|

|

YOUNG’S MODULES (x10Kg/mm²) At Room Temp.

|

2.9~3.1

|

| POISSON’S RATIO |

0.24~0.25 |

| K1C-VALVE (MN/m3/2)

[FRACTURE TOUGHNESS] |

5.3 |

| VICKERS HARDNESS (Kg/mm²)

AT ROOM TEMP. |

1400~1550 |

| FRICTION FACTOR (CERAMICS

TO CERAMICS) |

0.6 |

| THERMAL EXPANSION

COEFFICIENT (x10-7/°C) |

33~35 |

| THERMAL CONDUCTIVITY (Kcal/mh°C)

AT 100°C |

16~17 |

| THERMAL SPALLING RESISTANCE

(°C) |

750~800 |

|

WEIGHT INCREASE BY OXIDATION IN AIR (mg/cm²) AT

1,200°C x 24 hours

AT 1,400°C x 24 hours |

0.2~0.5

_ |

|

ELECTRICAL RESISTIVITY (W·cm)

At Room Temp. At 1,000°C |

>1016

1013~1014 |

STANDARD SIZES (in mm)

|

O.D.

(D)

|

30 |

30 |

30 |

30 |

30 |

30 |

30 |

20 |

20 |

20 |

40 |

|

I.D.

(d)

|

20 |

20 |

20 |

20 |

20 |

20 |

20 |

14 |

14 |

14 |

30 |

| Length

(L) |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

400 |

500 |

600 |

1300 |

CORROSION RESISTANCE AGAINST MOLTEN METALS

|

METAL/

Temp.

|

(720

hours) |

|

Tin

300°C

|

|

|

Lead

450°C

|

|

|

Zinc

550°C

|

|

| Aluminum

800°C |

|

|

Copper

1,200°C

|

|

CHEMICAL STABILITY

| Chemical |

HF |

HCL/ HNO3 |

HCL |

HNO3 |

H2SO4 |

H3PO4 |

NaOH |

| Strength |

10% |

3/1 |

36% |

20% |

61% |

25% |

95% |

30% |

85% |

30% |

| At Room Temp. |

|

|

|

|

|

|

|

|

|

|

| At Boiling Point |

- |

- |

- |

|

|

- |

|

- |

|

|

Color Code

for Chemical & Corrosion resistance

| |

No change (decreased strength 0%) |

| |

Slight change (<30%) |

| |

Change (<50%) |

| |

Considerable change (>50%) |

For further

information please Email us at:

sales@tashika.co.jp

Back on top